Guided rods are cylindrical components used in various applications‚ including fishing and machinery‚ to align and control movement․ They ensure smooth operation and efficiency in both recreational and industrial contexts․

Definition and Purpose of Guided Rods

A guided rod is a cylindrical component designed to align‚ stabilize‚ and control movement in various applications․ In fishing‚ they guide the line‚ enhancing casting accuracy and reducing wear․ In machinery‚ they support pistons or drills‚ ensuring smooth operation and preventing misalignment․ Their primary purpose is to maintain precise control and durability across different industries․

The rods are crafted from materials like metal or advanced polymers‚ chosen for strength‚ corrosion resistance‚ and lightweight properties․ They are essential in both recreational fishing and industrial machinery‚ ensuring efficiency and reliability in performance․

Guided rods serve as critical elements in systems requiring precise alignment and durability‚ making them indispensable in their respective applications․

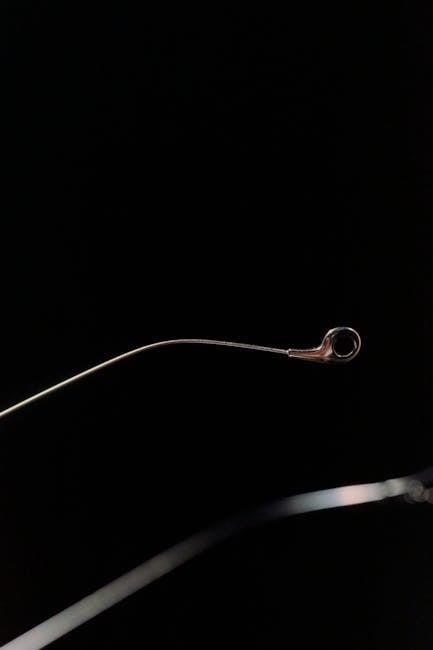

Fishing Rod Guides

Fishing rod guides are circular components attached along the rod’s length‚ directing the line during casting and retrieval․ They improve casting accuracy‚ reduce line wear‚ and distribute tension evenly․

Functions of Fishing Rod Guides

Fishing rod guides play a crucial role in enhancing the overall performance of a fishing rod․ Their primary function is to direct and control the fishing line during casting and retrieval‚ ensuring accurate targeting and maximizing casting distance․ Guides also distribute tension evenly along the rod‚ preventing it from snapping under pressure when fighting a fish․ Additionally‚ they minimize line wear and friction‚ which can lead to line breakage․ The layout and size of the guides are carefully designed to optimize sensitivity‚ allowing anglers to feel even the slightest bites․ Properly fitted guides enhance the rod’s balance and responsiveness‚ making them an essential component for both freshwater and saltwater fishing․ Their functionality directly impacts the angler’s ability to cast efficiently and handle fish effectively‚ making them a vital part of modern fishing equipment․

Evolution of Materials in Fishing Rod Guides

The materials used in fishing rod guides have undergone significant advancements over the years‚ enhancing their performance and durability․ Traditionally‚ guides were made from metal frames with ceramic or plastic inserts․ Modern materials now include high-quality stainless steel‚ titanium‚ and advanced ceramic compounds‚ which offer superior strength and corrosion resistance․ These innovations have led to lighter‚ more sensitive‚ and longer-lasting guides․ The evolution of materials has also improved heat dissipation‚ reducing the risk of line damage from friction․ Additionally‚ the development of corrosion-resistant coatings has made guides more suitable for saltwater fishing․ The use of advanced polymers and composite materials has further refined guide durability while maintaining their lightweight properties․ These material advancements have collectively contributed to better casting accuracy‚ reduced line wear‚ and enhanced overall fishing performance‚ making modern fishing rods more efficient and reliable than ever before․

Mechanical Applications of Guided Rods

Guided rods are essential in machinery‚ providing alignment and support in hydraulic and pneumatic cylinders․ They ensure smooth operation in heavy-duty applications‚ including steering and suspension systems in trucks․

Role of Guide Rods in Machinery

Guide rods play a crucial role in machinery by ensuring proper alignment and support for moving components․ In hydraulic and pneumatic systems‚ they stabilize piston rods‚ preventing misalignment and wear․ They are essential in applications like steering and suspension systems of heavy trucks‚ where precise movement is critical․ By guiding components accurately‚ they enhance operational efficiency and reduce the risk of mechanical failure․ Guide rods also protect piston rods from damage during assembly and operation‚ ensuring smooth‚ consistent performance․ Their durability and corrosion resistance make them indispensable in industrial settings‚ contributing to the overall reliability and longevity of machinery․ Properly functioning guide rods are vital for maintaining the integrity and functionality of various mechanical systems across industries․

Types of Guide Rods and Their Importance

There are several types of guide rods‚ each designed for specific applications․ In machinery‚ they include piston rod guides‚ steering rod guides‚ and tie rod guides‚ ensuring alignment and stability․ Fishing rods use line guides made from materials like ceramic or stainless steel‚ enhancing casting accuracy and line durability․ Heavy-duty guide rods‚ such as those in hydraulic systems‚ are built for strength and durability‚ while lightweight versions are used in precision instruments․ Corrosion-resistant guide rods are essential for marine environments‚ preventing degradation from saltwater exposure․ The diversity in guide rod types reflects their adaptability to different industries‚ ensuring optimal performance in each application․ Their importance lies in their ability to enhance efficiency‚ reduce wear‚ and ensure smooth operation across various mechanical and recreational systems․

Materials and Construction

Guided rods are crafted from materials like ceramic‚ stainless steel‚ and advanced polymers‚ ensuring strength‚ durability‚ and corrosion resistance․ These materials enhance performance and longevity across various applications․

Impact of Materials on Performance

The choice of materials significantly influences the performance of guided rods․ High-quality materials like ceramic‚ stainless steel‚ and advanced polymers provide exceptional strength‚ durability‚ and resistance to wear and tear․ These materials ensure that guided rods can withstand harsh conditions‚ including saltwater environments and heavy mechanical stress․ Ceramic guides‚ for instance‚ offer superior heat dissipation and a smoother surface‚ reducing friction and enhancing casting accuracy․ Stainless steel guides are prized for their corrosion resistance‚ making them ideal for marine applications․ Advanced polymers‚ on the other hand‚ combine lightweight properties with remarkable strength‚ allowing for more sensitive and responsive fishing experiences․ The evolution of materials has led to guided rods that are not only more durable but also more efficient‚ catering to both recreational and industrial needs․

Corrosion Resistance and Durability

Corrosion resistance and durability are critical factors in the performance of guided rods‚ especially in harsh environments․ Materials like stainless steel‚ titanium‚ and high-quality polymers are commonly used to enhance these properties․ Saltwater fishing‚ for instance‚ demands guides that can withstand corrosive conditions without compromising strength․ Modern designs often feature protective coatings or inserts‚ such as ceramic‚ to further resist corrosion and reduce friction․ Durability is ensured through robust construction‚ preventing wear and tear from frequent use․ Proper maintenance‚ such as cleaning and lubrication‚ can extend the lifespan of guided rods․ The combination of advanced materials and meticulous engineering ensures that guided rods remain reliable and functional over time‚ whether in fishing or industrial applications․

Evolution of Guided Rod Technology

Guided rod technology has advanced significantly‚ evolving from traditional materials to lightweight‚ corrosion-resistant designs․ Innovations in engineering and materials science have enhanced performance‚ durability‚ and efficiency across various applications․

Advancements in Design and Functionality

Recent advancements in guided rod design have focused on improving durability and performance․ Lightweight materials‚ such as advanced composites and corrosion-resistant alloys‚ are now commonly used to enhance strength and reduce weight․ These innovations allow guided rods to withstand harsh environments‚ including saltwater and high-stress industrial settings․ Additionally‚ modern manufacturing techniques have enabled the creation of more precise and efficient guide systems․ For instance‚ in fishing rods‚ the placement and size of guides are optimized to improve casting accuracy and sensitivity․ Similarly‚ in mechanical applications‚ guided rods now feature smoother surfaces and better alignment capabilities‚ reducing friction and wear․ These design improvements have significantly extended the lifespan and functionality of guided rods across various industries‚ making them indispensable in both recreational and industrial contexts․ The integration of advanced materials and engineering has truly revolutionized the performance of guided rods․

Future Trends in Guided Rod Development

Future trends in guided rod development are expected to focus on advanced materials and smart technologies․ Researchers are exploring the use of nanomaterials and self-lubricating surfaces to enhance durability and reduce maintenance․ Additionally‚ the integration of sensors and IoT connectivity could enable real-time monitoring of rod performance‚ predicting potential failures․ In fishing‚ rods may incorporate adaptive guides that adjust to different line weights and fishing conditions․ For industrial applications‚ there is a growing interest in lightweight‚ corrosion-resistant materials that can withstand extreme environments․ Sustainable manufacturing processes are also likely to play a key role‚ reducing environmental impact while maintaining high performance standards․ As technology advances‚ guided rods will become more versatile‚ efficient‚ and intelligent‚ catering to both recreational and industrial needs․ These innovations promise to redefine the capabilities of guided rods across various industries․